To 1st and 2nd year undergraduate students

/

To 3rd year undergraduate students

/

For those who are considering entering graduate school

/

To 1st and 2nd year

undergraduate students

〜On choosing a laboratory 〜

In our mechanical engineering program, students start looking for a laboratory for their graduation research around October of their junior year, before they are assigned to a laboratory in December. Of course, I recommend that you make your own decision on which laboratory to join. Deciding on a laboratory early on will give you direction and purpose, while taking classes. As with anything, early preparation is the key to success. You can visit our laboratory at any time to learn about what we are researching. Our laboratory conducts computer simulations; therefore, we do not have any experimental equipment. You can see the student rooms and high-performance computers. Nevertheless, you are always welcome to come and ask laboratory staff about our research; though if possible, it is better to confirm our schedule in advance by e-mail. In the past, there were students who heard about our research as first- or second-year undergraduates and joined our laboratory for their graduation research. If you wish, we can also prepare desks and computers for you to use in the laboratory, just like our laboratory students, allowing you to experience computer simulations firsthand. Please do not hesitate to contact us if you wish to have a laboratory experience.

To 3rd year undergraduate students

〜Introduction to graduation research〜

To 3rd year

undergraduate

students

〜Introduction to graduation research〜

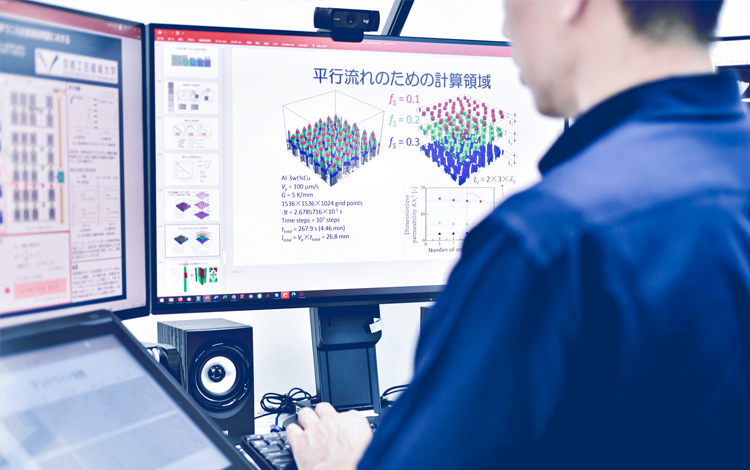

In our laboratory, we conduct research using computer simulations.Please refer to the “RESEARCH” page for details about our research. We are mainly interested in predicting the microstructures of metallic materials formed during working processes. Recently, our research has focused on the reproduction and clarification of solidification phenomena in casting, welding, 3D printing, etc. In our research, it is necessary to simultaneously consider solid–liquid phase transformations (solidification and melting), heat and mass transport, liquid flow, solid motion, and solid deformation, which requires knowledge of solid mechanics, materials science, fluid mechanics, and computational mechanics. In other words, this is research where you can simultaneously learn about the strength of materials, fluid mechanics, and heat transfer. In addition to solidification, our research covers grain growth and recrystallization that occur during the heat treatment of solid metallic materials. We are also researching how to predict the microstructures of magnets, batteries, and thin films, which will be important in the future. We conduct this state-of-the-art research by applying principles of data science. Beyond predicting microstructures, we also research a wide range of other topics, such as evaluating the mechanical behavior of microstructured materials, optimal design of structures, and construction of multi-phase flow models.

In our work, we mainly use a numerical model called the phase-field method. We also use the direct solution of the Navier–Stokes equations and the lattice Boltzmann method to simulate liquid flow. In addition, the finite element and particle methods are used to simulate the deformation of solids. Furthermore, we use molecular dynamics for numerical simulations at the atomic scale. Hence, we conduct research using various numerical simulation methods, while mainly relying on the phase-field method. Another feature of our laboratory is high-performance computing (HPC). We use supercomputers and graphics processing units (GPUs) to perform large-scale simulations that are impossible with ordinary personal computers. We are also actively conducting research using data science methods, such as data assimilation and machine learning, in combination with HPC. We believe that the combination of HPC and data science technologies will be significant in the future. Therefore, it would be valuable to acquire this knowledge while you are a student.

For those who are

considering entering graduate school

Master’s program

We welcome students from outside the university and from overseas. Our laboratory is a part of the Mechanophysics Master’s program. We are always ready to explain our research; please contact us, either in-person at our laboratory or online. Please refer to the “RESEARCH” page for more information about the research topics in our laboratory.

Doctoral program

We actively encourage students to enter the doctoral course in our laboratory. We also welcome students from overseas. In the uncertain and diverse society of the future, the power and originality of the individual will become increasingly important. In addition, a doctoral degree is essential for international activities. Therefore, we encourage you to enter the doctoral course and develop your own unique abilities. A doctoral course can lead to future opportunities at universities or research institutes, as well as in industry. For example, a doctoral degree is a requirement in some foreign-affiliated companies. Please feel free to contact us if you are interested in the doctoral program.

For Companies

〜Regarding joint research〜

In our laboratory, we predict the formation and properties of various material microstructures using computer simulations (see “RESEARCH” page for details). We mainly use phase-field, finite element, lattice Boltzmann, molecular dynamics, and crystal plasticity theory methods. In addition, we utilize HPC technologies, such as GPU simulations, parallel computing, and supercomputers. We are also developing numerical analysis techniques, such as the adaptive mesh refinement scheme. Please feel free to contact us if you have any questions or are interested in conducting joint research.

Professor Tomohiro Takaki

http://www.cis.kit.ac.jp/~takaki/index-jp.html

Assistant Professor Shinji Sakane

http://www.cis.kit.ac.jp/~sakane/

Research Introduction

http://www.cmd.kit.ac.jp/en/research.html

/

/