RESEARCH

RESEARCH

Metallic materials are made into products through various working processes, such as casting, hot working, cold working, heat treatment, and plastic deformation. During these processes, material microstructures change significantly depending on the process conditions, and various material properties, such as mechanical properties, change depending on the changes in the material microstructure. Therefore, to improve the properties of materials, it is essential to appropriately control the microstructures.

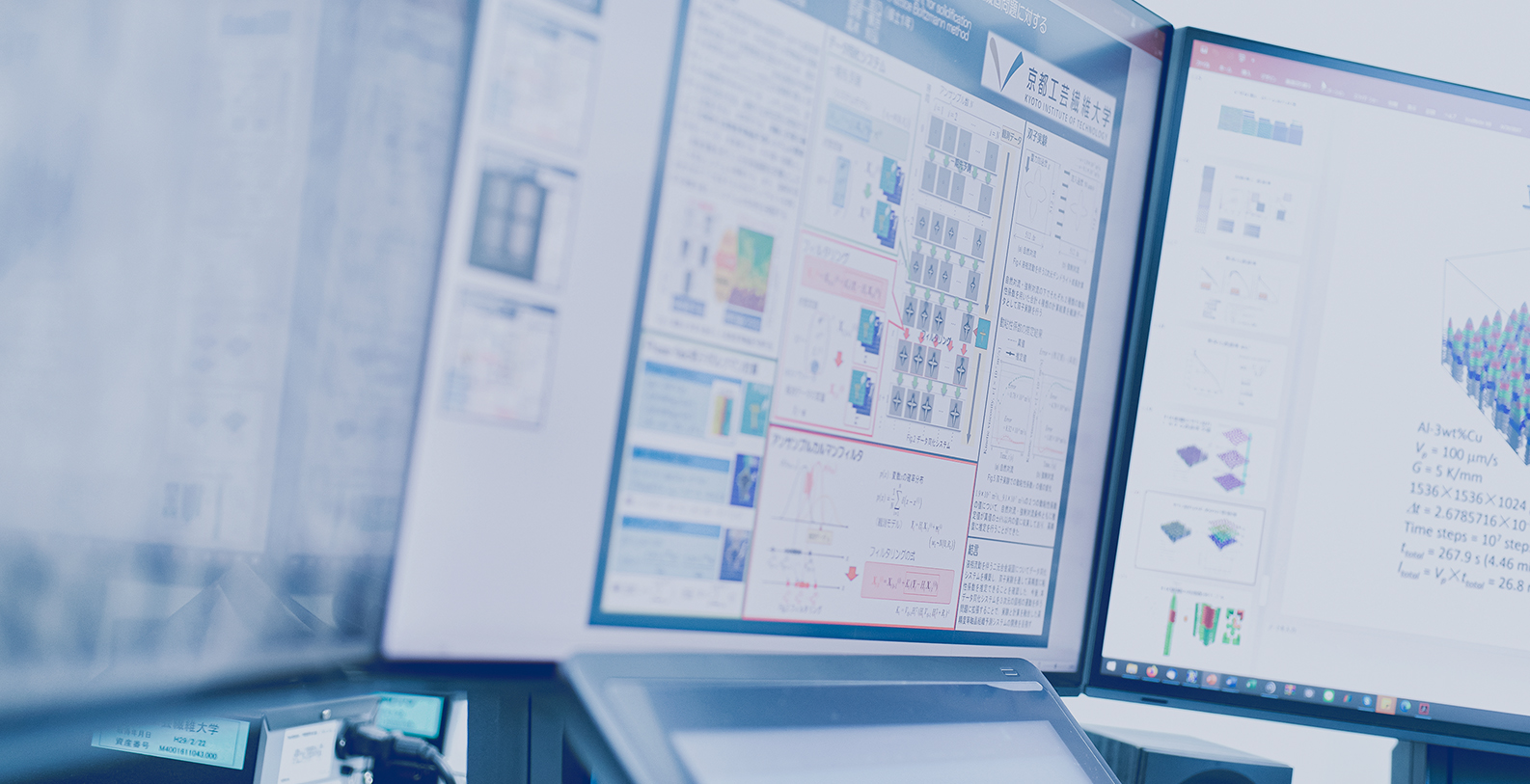

In this laboratory, we develop computer-aided prediction techniques for material microstructures formed in a series of working processes, using various numerical models and numerical schemes. We are also clarifying the phenomena that occur during the formation process of material microstructures using numerical methods. In particular, we use the phase-field method as the main numerical model, which is the most powerful numerical model for expressing material microstructure evolution on a meso-scale. Furthermore, we conduct studies in which the phase-field method is applied for the prediction of material microstructures as well as to study various phenomena, such as crack propagation, topology optimization, and multi-phase flow.

ABOUT

ACCESS

ACCESS

Computational Materials Design Lab.

Faculty of Mechanical Engineering

Kyoto Institute of Technology

Computational Materials Design Lab.

Faculty of Mechanical Engineering

Kyoto Institute of Technology

The 2nd floor of 10th Building

Hashigami-cho, Matsugasaki, Sakyo-ku, Kyoto

606–

8585 Japan

/

/